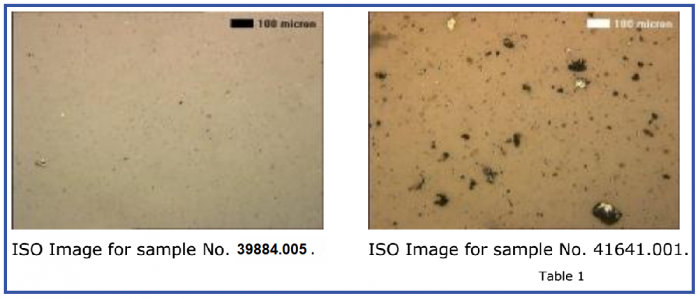

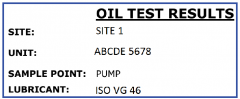

Oil Analysis Report Format

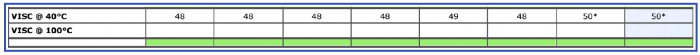

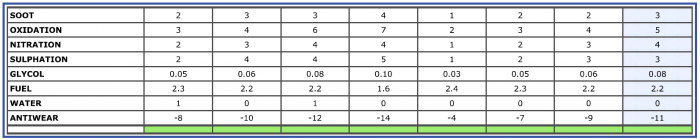

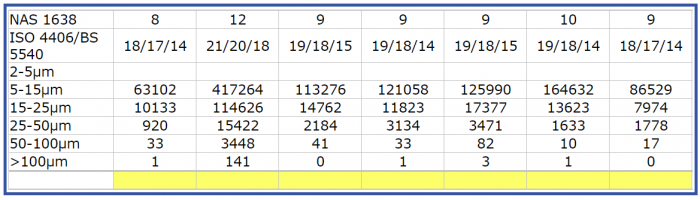

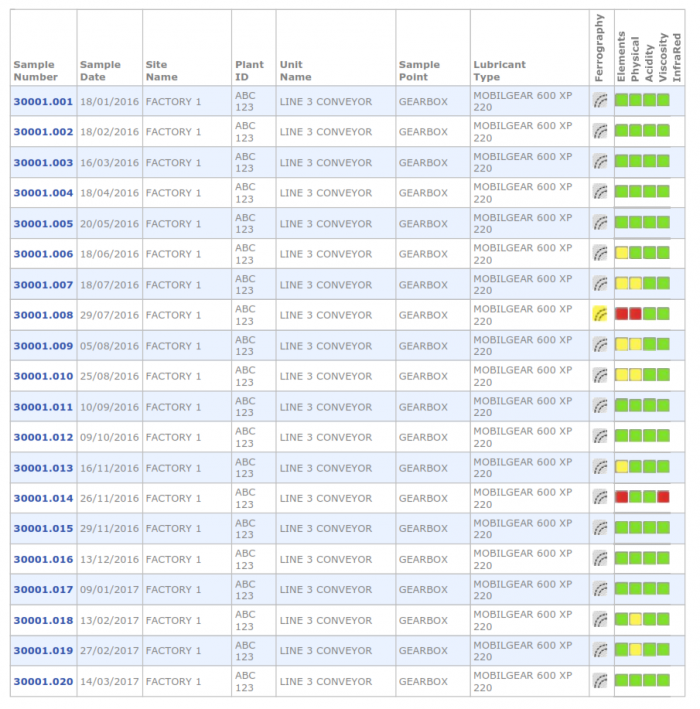

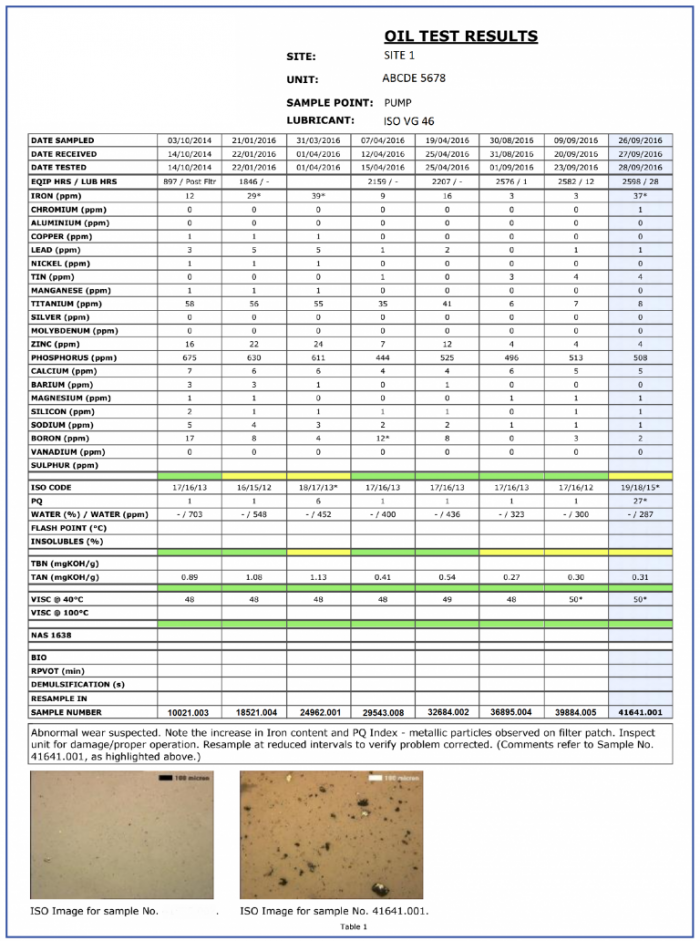

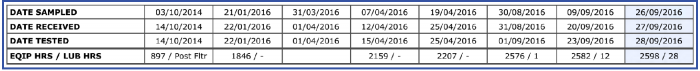

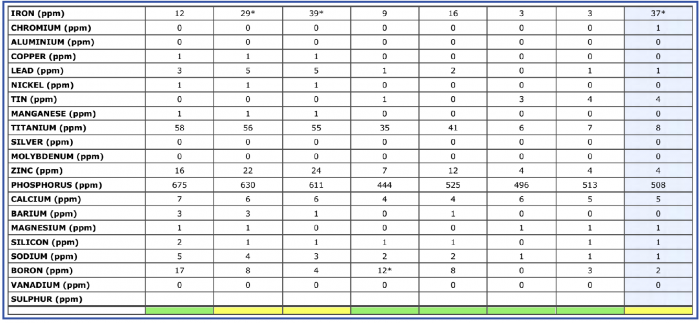

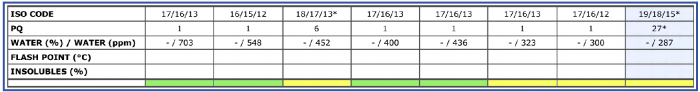

Here we will dissect a page from a typical oil analysis report. We do our best to make our reports as clear and intuitive as possible, but there is no harm in spending a few minutes to familiarise yourself with the layout. If multiple samples are being reported you may find that an overview page, has been included at the beginning of the report. This lists the samples in the order of their sample number. Sample date, site name, plant ID, unit name, sample point and lubricant type are also listed together with a “traffic light” status of the different test categories: Ferrography – indicates if an Analytical Ferrography test has been completed, staying grey if not done, and uses colour to indicate the status of the ferrographic investigation. Elemental Analysis – Wear, Contaminant and Additive elements. Physical Tests – ISO Code for particulates, PQ Index, Water Content, Flash Point and Insolubles/Soot, where available. Acidity – Total Acid Number (TAN) and Total Base Number (TBN), pH for aqueous fluids. Viscosity – Viscosity at 40oC and 100oC where appropriate. Infra Red Spectroscopy – where available. The significance of the colours is as follows:

- Green – Normal Condition. No action required. Any parameters that may be highlighted are to be monitored by the lab when the next scheduled sample is sent in – this is to verify any potential early warnings of abnormal trends.

- Yellow – Caution, Abnormal or Marginal Condition. One or more parameters outside of normal range or abnormal rate of change observed. Refer to comments. Closer monitoring is usually recommended to confirm trend – see highlighted parameters. Condition to be reviewed by the end user, who may have greater insight into the situation and can initiate a dialogue with the lab, providing feedback, and take appropriate action if any is necessary. Corrective action may need to be considered, however may be possible to postpone depending on other factors (operating schedules, maintenance plans, cost, different tolerances or limits due to operating environment and conditions).

- Red – Critical Condition. One or more parameters are significantly outside the normal range and could lead to further wear or failure if left unattended. Refer to comments. Corrective action is required. In some cases this is caused by incorrect identification of the sample or poor sampling technique – the lab is often able to highlight such possibility and recommend that an urgent repeat sample is provided to verify.

- Patch Test ISO Cleanliness Code

- PQ Index

- Water content in either %, ppm or both*

- Flash Point

- Insolubles (% Soot)

- <0.05% is displayed as 100 ppm

- Trace water contamination is equivalent to 0.05% and displayed as 500 ppm

- 0.10% is displayed as 1000 ppm

- >0.10% is displayed as 1500 ppm

- >>0.10% is displayed as 2000 ppm

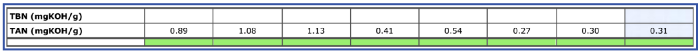

The condition of the sample with respect to physical contaminants is indicated with a colour bar at the bottom of the section. The next section describes the sample’s acidity and contains results of acid and base number measurements. For aqueous samples, such as anti-freeze coolants, acidity and alkalinity are expressed in terms of pH and reported in the TAN field with the suffix “pH” (e.g. “9.6pH”). The condition of the sample with respect to its acidity is indicated by the colour of the bar at the bottom of the section.